- Home

- Agriculture

- Planting Equipment

- Drawn Planters

- 1775NT 12Row30

1775NT 12Row30

- 12 rows on 30-in. spacing

- Available with optional ExactEmerge™ or MaxEmerge™ 5e row unit or standard in mini-hopper, 1.6-bu., or 3-bu. MaxEmerge™ 5 row unit

- Insecticide option for mini-hopper and 1.6-bu.

- 3-section frame flexes 21 degrees up & down with narrow transport of 12 ft.

Price may vary based on location and options.

SeedStar 4HP monitoring system

SeedStar 4HP monitoring system lets you view multiple functions at once in a very simplified overview layout. Just touch the bar chart and zoom into any row for detailed information regarding that row. Highly configurable run pages that let you arrange SeedStar modules by operator preference. Complete simplified setup from work setup page instead of having multiple applications to open.

John Deere Operations Center

What do you do with all your data once you've collected it? Put it to work for you with John Deere Operations Center, where you have the ability to turn you valuable information into a plan of action. Collect data easily, review to make accurate decisions and share with your trusted advisors. Within this online portal, you can see average yield, total yield, average moisture seeding variety and rates and more. Every time you're done seeding a field, that information is waiting for you in the Operations Center to make adjustments improvements for the next year.

features

Planter auxiliary camera

Planter auxiliary camera

The planter auxiliary camera utilizes an adjustable magnetic mounting base. This allows customers the ability to move and adjust the field of view to see what’s most important to them.

- Camera is integrated into the SeedStar™ 5 planter Ethernet system, video is streamed to the CommandCenter™ display

- Camera is mounted to an adjustable magnetic base allowing customers full adjustability of their field of view

- Configurable with existing programmable video triggers

- Compatible with model year 2025 and newer SeedStar 5 planters and performance upgrade kits

- Mirror image view and adjust field of view from the video app on the G5 CommandCenter™ display

Adjustable magnetic camera mounting bracket

Adjustable magnetic camera mounting bracket

Picture of the liquid fertilizer level sensor

Picture of the liquid fertilizer level sensor

Liquid fertilizer level sensing is available on model year 2026 electric drive planters.

Fertilizer level sensing allows farmers to know how much liquid fertilizer is left in the tank from the convenience of the cab. The fertilizer level is displayed on the G5 CommandCenter™ Display in the SeedStar™ app.

- Better coordinate fertilizer tendering plans by knowing how many total gallons of liquid fertilizer are left on the planter.

- See total gallons of liquid fertilizer left on both planter and tractor if tractor is equipped with ExactRate™ tractor tanks.

- Enables customizable low fertilizer tank level warning alarms to prevent running out of liquid fertilizer.

- Fertilizer tender drivers and farm managers can remotely view fertilizer tank levels from a smart connected device using the John Deere Operations Center™ mobile app.

- Removes the need for the operator to manually set the fertilizer tank volume and enter the specific gravity.

View cumulative fertilizer tank levels on both 8RX ExactRate tanks and planter liquid fertilizer tank levels on the G5 CommandCenter Display

View cumulative fertilizer tank levels on both 8RX ExactRate tanks and planter liquid fertilizer tank levels on the G5 CommandCenter Display

CCS tank levels displayed in the SeedStar™ application

CCS tank levels displayed in the SeedStar™ application

Seed level sensing is available on all model year 2026 electric drive planters equipped with Central Commodity System (CCS) tanks operating on the SeedStar™ 5 planter application.

Seed level sensing gives farmers better knowledge of planter seed levels. This reduces the risk of running out of seed while planting also allowing farmers to better manage seed tendering logistics to have the seed in the right place at the right time.

View individual and total tank levels from the G5 CommandCenter™ display in the SeedStar app:

- Better plan tendering logistics with seed volume or seed percentage remaining

- Remotely view seed tank percent levels from your computer using John Deere Operations Center™ or from your connected smart device using the John Deere Operations Center mobile app

- Individual tank level displayed helps farmers prevent one tank emptying before the other

- Enables customizable low seed tank level warning alarms

Customizable tank level alarms - view tank 1, tank 2 and total seed volume on G5 Display

Customizable tank level alarms - view tank 1, tank 2 and total seed volume on G5 Display

ExactShot delivers product directly onto the seed in-furrow, eliminating waste between seeds

ExactShot delivers product directly onto the seed in-furrow, eliminating waste between seeds

Save on in-furrow fertilizer cost with ExactShot liquid fertilizer dosing system.

High input costs reduce the profitability of any operation. ExactShot can save growers up to 66% of the cost of in-furrow applied nutrients improving their use and efficiency while protecting yield loss along the way. It does this by dosing the product on top of the seed, in the furrow, eliminating the application of product between seeds.

Using less product also results in fewer stops to refill your tanks, improving the overall efficiency of your planting operation.

- Reduce in-furrow fertilizer use up to 66 percent*

- Increase time between starter liquid fertilizer refills in the field

- Maximize nutrient use efficiency by placing product only on the seed

- Enable the potential to add higher-cost or additional applications

*NOTE: Based on internal tests of a prototype ExactShot system performed across 21 farms in six Midwestern states applying a 5.1-cm (2-in) dose on seeds with 15.2-cm (6-in) in-row seed spacing. ExactShot requires a per acre fee when in dosing mode. In continuous mode there is no fee required.

How does it work?

When paired with John Deere’s ExactEmerge™ BrushBelt™ technology, the system tracks each seed with infinite accuracy from meter to seed trench, synchronizing each dose with the exact timing of the seed drop. Placing the solenoid directly above the nozzle tip, below the row-unit, adds an additional level of accuracy with each dose not found in similar products.

Two modes of operation

The overall benefits of ExactShot may vary with different products, crop types, soils, etc. In these scenarios, the system can be switched to a more traditional continuous stream of product directly from the display. This gives operators the flexibility to quickly change their application method without the need to change hardware on the planter.

Dosing mode screen on G5 display

Dosing mode screen on G5 display

Continuous mode screen on G5 display

Continuous mode screen on G5 display

Agronomic benefits and savings

Multiple field studies* have shown yields were maintained when the same effective application rate of in-furrow starter fertilizer was dosed directly onto the seed compared to the traditional continuous stream. In some highly responsive instances, as the local rate was increased, yield also increased without adding cost to the application.

By reducing rates, customers can increase their overall profit margins, receiving a higher return on investment with 18.7-L/ha (2-gpa) dosing on-seed compared to 56.1-L/ha (6-gpa) continuous stream. View our ExactShot calculator to see how reduced rates can impact your operation.

Reducing the amount of fertilizer used also reduces the risk of nutrients leaching into nearby rivers, lakes, and ponds.

Additionally, because ExactShot significantly reduces how much product is needed, growers can also gain the ability to use beneficial products in-furrow during planting like biologicals, fungicides, and liquid insecticides that may otherwise be too costly to apply.

*NOTE: Internal tests of a prototype ExactShot system performed across 21 farms in six Midwestern states. ExactShot requires a per acre fee when in dosing mode. In continuous mode there is no fee required.

24-row 1775NT Planter equipped with ExactRate system

24-row 1775NT Planter equipped with ExactRate system

The ExactRate fluid transfer system pairs planters seamlessly with the ExactRate tractor tanks. It provides an easy connection point to allow transfer from the ExactRate tractor tanks back to the planter tank. This enables up 6056 L (1600 gal.)* of combined capacity between the tractor and planter tanks.

- Factory installed

- Designed and tested by John Deere to ensure the lines won’t pinch when folding

- Easily attaches to the ExactRate tractor tanks

ExactRate is available on the following models: 1775NT, 1795, DB44, DB60, and DB66.

*NOTE: 6056 L (1600 gal.) assumes a 2271-L (600-gal.) tank on a 24-Row 1775NT Planter as well as the 3785-L (1000-gal.) capacity on the 8RX Tractor.

24-row 1775NT Planter equipped with ExactRate fluid transfer system

24-row 1775NT Planter equipped with ExactRate fluid transfer system

Liquid tank mounted on a 24-row 1775NT Planter

Liquid tank mounted on a 24-row 1775NT Planter

John Deere factory-installed liquid tanks offer a convenient way to carry fluid on the planter frame. Styling cues match the CCS™ system tanks, and all brackets and mountings are 100 percent factory installed.

- Factory installed

- Up to 2271 L (600 gal.) of fluid capacity

- Clear sight tube to check fluid level

- Air bleed and overflow protection

Liquid Tank mounted to a 24-row 1775NT Planter

Liquid Tank mounted to a 24-row 1775NT Planter

John Deere factory-installed tracks on a 24-row 1775NT Planter

John Deere factory-installed tracks on a 24-row 1775NT Planter

Alleviate the ground pressure in your center section with John Deere factory-installed tracks. The tracks offer a larger footprint to allow for less compaction and better flotation.

- 91.7-kPa (13.3-psi) ground pressure (based on weight distribution of a fully ballasted 24-row 1775NT Planter over track flat plate area)

- 32.2-km/h (20-mph) transport speed

- Half-full carrying capacity during transport on a 24-row 1775NT Planter

- 100 percent factory installed

NOTE: Factory-installed tracks are only available on the 1775NT Planters.

These factory-installed tracks increase the planter’s flat plate area from 722.6 cm2 to 2683.9 cm2 (112 sq in. to 416 sq in.), which leads to reduced compaction in the planter’s center rows. When paired with the four tracks on the 8RX Tractor, the full solution provides just 103.4 kPa (15 psi) to the ground.

NOTE: Transport duration, carrying capacity, and transport speed assumes the planter is being pulled behind an 8RX with 61-cm (24-in.) belts. See the tractor/planter Operator’s Manual for additional transport restrictions and information.

Tracks are also available as an aftermarket attachment on 1775NT 12-row, 16-row, or 24-row hydraulic drive and electric drive planters.

Key benefits include:

- Reduced compaction in the planter’s center rows

- Better flotation

- Low maintenance, since all joints on the tracks are lubricated for life

- Increased transport speeds (32.2 km/h [20 mph]) and cylinder walking features available when installed on model year 2022 electric drive planters

Compatibility:

- All 1775NT 12-row, 16-row, and 24-row electric drive and variable rate drive machines

- All 1770NT 12-row, 16-row, and 24-row electric drive and variable rate drive machines

- Kits are not compatible with ground drive planters (and/or ground drive attachments)

24-row 1775NT Planter on tracks being pulled by an 8410RX model

24-row 1775NT Planter on tracks being pulled by an 8410RX model

LED light on stairs to the CCS™ system platform

LED light on stairs to the CCS™ system platform

As planting windows get tighter, many growers are working longer hours to get the seed in the ground. With the planter LED lighting package, John Deere delivers better visibility when planting a night.

- Four additional LED lights

- Improves visibility when planting at night

- Illuminates row-units when servicing at night

- Turns on when tractor lights are engaged

ExactRate pump assembly at rear of 16-row 1725C

ExactRate pump assembly at rear of 16-row 1725C

The ExactRate liquid fertilizer system is a factory-installed solution that provides you with accurate nutrient placement during planting. Previously, you would have to deal with the inconvenience of cumbersome aftermarket systems for a hydraulically driven variable-rate solution. With ExactRate, John Deere delivers a complete planting solution for liquid fertilizer users. You can choose between in-furrow or offset delivery methods. A high-rate option without openers is also offered from the factory. This system delivers:

- Up to 20 percent more accurate nutrient placement in a turn compared to a non-turn compensating system

- 1 to 12 percent (4.3 percent on average) reduction in inputs through row-by-row section control

- Ability to run up to 16.1 km/h (10 mph)

- Closed-loop speed and rate change compensation

- Full integration into the G5 Universal Display

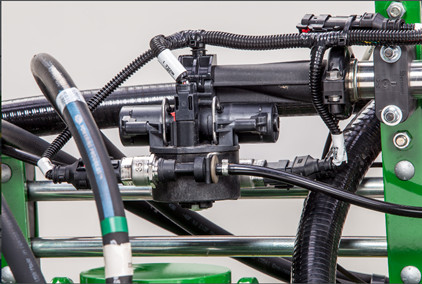

ExactRate nozzle body

ExactRate nozzle body

The ExactRate liquid fertilizer system is designed to take full advantage of the capabilities of ExactEmerge™ and MaxEmerge™ 5e planters. This factory-installed liquid fertilizer system delivers the same value as your electric drive planter including working at speeds faster than the traditional 8.05 km/h (5 mph), turn compensation, and row-by-row section control, all while accurately compensating for varying rates and speed changes. Additional features include row-by-row flow detection, as-applied documentation, and variable-rate capabilities.

Fertilizer flows from the tank to the pump, through a strainer and boom isolation valve, through a central flowmeter, and out to each nozzle body and row-unit for accurate delivery. The system is closed loop, meaning the pump and nozzle body duty cycle both adjust based on feedback received from the pressure sensor and central flowmeter. This design helps maintain an accurate application rate.

NOTE: ExactRate is not recommended for products that require agitation to maintain suspension.

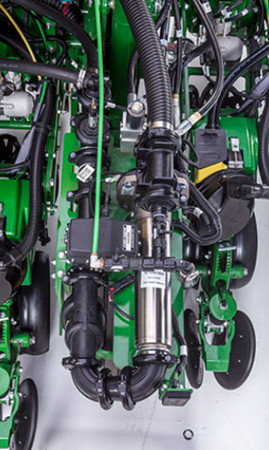

Pump

Pump assembly at rear of planter

Pump assembly at rear of planter

Instead of a tire-contact drive, a hydraulically driven centrifugal pump eliminates chain and sprocket adjustments to provide more speed flexibility over the entire rate range. This pump allows for a wide range of rate capabilities as well as strong durability. The wet seal design helps protect the pump if it is accidentally run dry for a short time.

Strainer

A strainer helps collect suspended particles and prevent them from causing blockages in the distribution system and nozzle bodies.

Boom isolation valve

The valve prevents the tank from draining out if there is a leak in the distribution system. If the pump is on, the valve opens to allow flow. When the pump is off, the valve closes.

Central flowmeter and pump pressure sensor

The central flowmeter and pump pressure sensor provide the rate control system feedback on flow and pressure to ensure an accurate application rate across the entire planter width. The flowmeter also supplies the as-applied rate data.

Distribution system and nozzle body

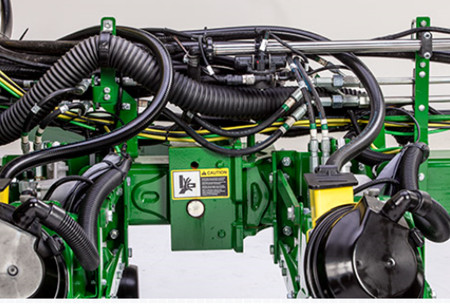

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

Distribution system and nozzle bodies routed on the wing of a 12-row 1775NT

The 2.5-cm (1-in.) stainless-steel distribution lines not only reduce corrosion, but they also provide a clean integrated look. The distribution system is pressure tested at the factory to reduce the risk of leaks.

John Deere has leveraged ExactApply™ technology and capabilities from the sprayers to enable row-by-row section control and turn compensation that matches the high-performance planters. With ExactRate, there are no orifice changes for rate or speed adjustments, saving you time and effort while limiting exposure to product. Pulse-width modulation technology varies duty cycle (opening and closing of the valve) in the nozzle bodies in conjunction with flow and pressure measured from central flowmeter and pressure sensor controlling the system pump. The ExactRate liquid fertilizer system uses one nozzle body for two rows, limiting the number of parts and complexity on each machine. While you’re in the cab, you can keep an eye on each row with flow detection integrated into the Gen 5 display. The system warns you if it detects a variance in an individual row’s flow. A pressure sensor integrated into the nozzle body will detect a flow reduction or overapplication on the row.

Keypad at rear of planter

Keypad at rear of planter

Just like on the sprayers, the keypad at the rear of the machine lets you conveniently perform a nozzle flow check to ensure product is coming out of each row before going to the field.

Rate Controller

The ExactRate liquid fertilizer system is compatible with the John Deere Rate Controller 2000 and GreenStar™ Rate Controller if a producer wants to apply a second product using a separate distribution system.

Direct injection

The ExactRate liquid fertilizer system does not have direct injection capabilities on the product being applied. If direct injection is needed on the secondary product, an additional rate controller is required.

NOTE: ExactRate system and John Deere Rate Controller 2000 with Raven ICD Direct Injection system is supported. ExactRate system and GreenStar Rate Controller with Raven ISO Direct Injection system is not supported.

ExactRate app on G5 Display

Easily adjust target rate and speed without leaving your seat. With turn compensation, inner and outer rates are automatically adjusted to maintain consistent application across the full width of the planter. This ultimately reduces the risk of seed burn by over application (turn compensations require a global positioning system [GPS] receiver). Another helpful feature is row-by-row section control for reduced overlap on headlands and waterways. G5 Documentation creates as-applied maps showing what product was applied where, providing accurate record-keeping.

It is very challenging to get the crop planted during the optimum planting window or as close to the optimum planting day as possible. Rate-of-yield loss accelerates greatly after the optimum window has passed. This is especially true in the northern U.S. and Canada. ExactEmerge maintains accurate speed placement at higher speeds; growers can avoid missing that peak planting time, thereby helping to get the highest crop yields.

Yield loss after optimum planting day

Yield loss after optimum planting day

With the BrushBelt trench delivery system, the spacing in the trench does not change from even to uneven terrain. This can be a problem with a traditional seed tube. Seed bounce and ricochet may occur as slopes increases, ultimately decreasing seed spacing performance.

The design of the BrushBelt system provides the best solution for the lowest release of seed to the bottom of the trench. The use of a brush provides the meter with an infinite amount of placement opportunities for each seed. This is what gives producers the confidence that every seed will have the desired spacing that a seed tube cannot provide.

Maintenance-free BrushBelt system

Maintenance-free BrushBelt system

When the brush comes around the pulley, it expands and allows the seed to be transferred from the bowl to the brush very easily. The brush then carries the seed down toward the trench, ensuring that there is no movement as it moves down the length of the cartridge.

Once the brush reaches the lower pulley, the BrushBelt system expands again to loosen the grip on the seed, and the centrifugal force releases the seed. Another advantage with the BrushBelt system and cartridge at all speeds up to 16.1 km/p (10 mph) is the ability to match the seed rearward trajectory to the forward ground speed of the planter. This provides a dead drop of the seed with no bounce and no roll at the bottom of the trench.

BrushBelt conditioner engages brush bristles

BrushBelt conditioner engages brush bristles

John Deere’s ExactEmerge cartridge is self-cleaning. When an operator uses seed treatments or is forced to plant in less than ideal soil conditions, the design of the trench delivery system sheds buildup from the BrushBelt. A brush conditioner is located at the bottom of the cartridge to remove remaining residue and prevent the bristles from sticking together.

Brush proximity helps clean sensor

Brush proximity helps clean sensor

Another advantage over a seed tube is that the BrushBelt system also acts as a cleaner to the seed sensor compared to a seed tube.

Sensors for trench delivery system

Sensors for trench delivery system

Reflective seed sensor

Reflective seed sensor

Sensor on trench delivery system

Sensor on trench delivery system

On all ExactEmerge row-units, each cartridge is equipped with sensors. As the seeds are being delivered through the BrushBelt delivery system controls, they pass the reflective seed sensor. The delivery system slides every seed past the seed sensor to read and send the signal to the controller. The seed sensor and design can provide sensor performance at higher seeds per second with no population adjustment as needed with seed tube sensors. This seed sensor data is actual row-unit performance data. In comparison, seed tube sensors add 10 percent population in soybean planting to adjust for the seeds missed due to placement within the seed tube. The BrushBelt system holds each seed in place until released in the trench, allowing the seed sensor a more accurate read.

BrushBelt removed from trench delivery system

BrushBelt removed from trench delivery system

The BrushBelt system requires no maintenance and has a wear life designed to match the wear life of the other wear components. Since operations vary, as do soils and field content, it is recommended to replace the BrushBelt after noticeable wear or decreased performance.

Changing the belt is easy. One latch removes the meter over the trench delivery system. Grab the cartridge by the grip and pull toward the body, releasing it from the electric motor fitting. Lift the trench delivery system up and remove the sensor wiring harness to completely pull the cartridge out of the row-unit.

There are two plastic covers that snap off to uncover the belt; remove the covers and then twist the circular spring tensioner dial with the yellow arrow on it to release the tension on the springs. Once tension has been removed, pull the belt out. It is also recommended to change the stainless-steel wear strip at this time as well, which also slides right out of place without the use of tools.

NOTE: It is recommended to use a talc/graphite mixture with ExactEmerge. Best results have been 80 percent talc and 20 percent graphite. For certain regions and territories, talc and talc/graphite mixes are restricted from use; in this case, use a wax-based fluency agent.

SeedStar 5 screen example

SeedStar 5 screen example

Overview

SeedStar 5 is the latest monitoring software for John Deere planters available for Model Year 2025. This system is paired with G5 displays and Implement Ethernet to provide high-definition documentation, faster data speeds, and more information in the cab.

Benefits

- Faster data speeds

- High Definition (5Hz data) documentation

- Enables new technology like ExactShot and FurrowVision

- Building block for future planter automation

Additional details

Requirement:

- G5 Display

- Planter Implement Ethernet (included on model year 2025 planters)

- Building block for future planter information

Individual Row Hydraulic Downforce (IRHD)

IRHD system

IRHD system

IRHD has been specifically designed to meet the needs of producers that are looking to adjust to the toughest field conditions and provide maximum yield potential from field to field, season after season. IRHD works as a closed-loop downforce system that reacts quickly on an individual row basis to changing soil conditions supporting increased ground contact, which can lead to improved seed depth consistency. When setting planter downforce margin, the system will apply the needed downforce by row to maintain ground contact.

The system allows operators to maintain gauge wheel ground contact leading to desired seed depth placement. IRHD can adjust five times per second and make adjustments of 45.4 kg (100 lb) in less than a second. The system has a total range of applied downforce from 22.7 kg (50 lb) to 204.1 kg (450 lb) and utilizes the power beyond circuit on the tractor. IRHD is 58 percent faster than the active pneumatic downforce solution. Fast reaction and increased ground contact can lead to improved emergence. With uniform emergence, some studies have shown a yield impact from 5 percent to 9 percent.

IRHD is controlled through the G5 Display with SeedStar 5. As shown below, operators can view ground contact or applied downforce using the toggle button.

IRHD screen showing the ground contact graph

IRHD screen showing the ground contact graph

IRHD screen showing the applied downforce graph

IRHD screen showing the applied downforce graph

IRHD accumulator

IRHD accumulator

IRHD accumulator

The IRHD actuator is the foundation of ensuring accurate seed depth and seed-to-soil contact at higher planting speeds up to 16.1 km/h (10 mph). The newly redesigned IRHD actuator was designed with durability and optimal performance in mind. Consisting of a valve, pressure sensor, cylinder, and now, two accumulators, the new design allows the operator to reduce downtime with recharges instead of replacements. With two rechargeable nitrogen accumulators built into the new IRHD actuator, it maintains performance, even at low nitrogen levels. This allows reduced downtime for the operator, and optimal performance over entire operating range. Pressure control from the IRHD actuator ensures optimal system performance by dampening shocks from field obstacles while operating in the field. The reduction of shock loads prevents excessive wear and broken row unit components due to the new robust and durable design. Frequently worn parts such as the accumulator pistons and seals can be replaced. The actuator rod has an internal retention feature to prevent oil loss in the event of a row unit failure.

Heavy-duty parallel arm for IRHD Planter row units available

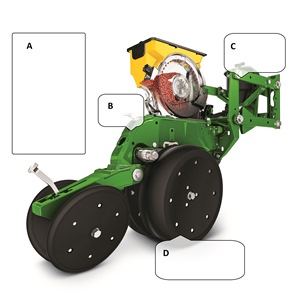

Downforce and margin example

Downforce and margin example

- A - Margin – amount of additional downforce applied to a row-unit above and beyond what is required for penetration to achieve planting depth. This additional weight will ride on the depth gauge wheels.

- 54.4 kg (120 lb) + 36.3 kg (80 lb) = 90.7 kg (200 lb) – 68 kg (150 lb) = 22.7 kg (50 lb) of margin

- B - Weight of row-unit - 54.4 kg (120 lb)

- C - Downforce – force that is applied to the row-unit by the air bag circuit - 36.3 kg (80 lb)

- D - Resistance from soil - 68 kg (150 lb)

Active downforce compressor assembly

Active downforce compressor assembly

A hydraulically driven compressor works with the G5 Display with SeedStar 5 systems to automate downforce control. Just set the row-unit target margin value and the active pneumatic downforce system works automatically. The system will make sure the planter maintains this value, achieving precise soil penetration, and consistent planting depth, without sidewall soil compaction. From the factory, the system is set at 45.4 kg (100 lb) target downforce margin but may be modified for varying field conditions. This frees the operator from constantly making manual downforce adjustments as conditions change.

This system offers a split-rank control feature for 1795 and DB Split-Row Planters. On split-row planters, active downforce will control the front and rear rows independently. This compensates for differing downforce requirements between the ranks that can be caused by things like different tillage or insecticide attachments and will help maintain an accurate planting depth and consistent margin across all the rows.

Active pneumatic downforce is available as factory installed or as an attachment for field conversion.

Set point row-unit downforce

Air compressor mounted on 1775NT outer hitch

Air compressor mounted on 1775NT outer hitch

On set point, the air compressor will be mounted on the outer hitch or frame assembly. Since the electric air compressor assembly is mounted on the outer hitch (as noted in the picture above) or frame, adjustments for row-unit downforce and related system pressures will be made electronically with the display.

When adjusting the amount of row-unit downforce using the display, the operator will select the amount of downforce (kg [lb]) to be applied across the planter. Depending on the soil conditions at hand, the operator might need to adjust the relative amount of row-unit downforce being applied during the planting operation. The integrated pneumatic downforce controls within the display will only allow for set-point operation and not automatic control as the planter is operating in different soil conditions. The pneumatic downforce system does not have the capability to automatically adjust downforce.

Pneumatic downforce provides convenient, simple adjustment of downforce for the whole planter from one location. The amount of downforce applied is infinitely adjustable from 6.8 to 181.4 kg (15 to 400 lb). Pneumatic downforce provides more consistent downforce throughout the range of row-unit travel than mechanical spring downforce systems.

Features include:

- 9.5-mm (3/8-in.) air delivery line instead of the 6.4-mm (1/4-in.) line used on model year 2010 and older planters.

- Air compressor assembly increased duty cycle. With this compressor, it provides a 47 percent increase in maximum air flow delivery compared to the prior air compressor.

- Pneumatic air bags with 9.5-mm (3/8-in.) air line inlets that have greater durability.

Pneumatic downforce compressor and gauge

Pneumatic downforce compressor and gauge

An improved compressor is used to charge the pneumatic system. This compressor can be located on the planter frame or in the tractor cab if desired. A gauge at the compressor indicates the amount of downforce being applied.

Integrated pneumatic downforce system

The functional features of the integrated system are the same as the standard pneumatic system, explained above, with the addition of control through the display.

Heavy-duty adjustable downforce springs

Heavy-duty adjustable downforce spring

Heavy-duty adjustable downforce spring

Planter row-unit downforce is an important factor to ensure consistent and proper depth control. The heavy-duty adjustable downforce feature provides up to 181.4 kg (400 lb) of downforce. There are four settings available to allow the operator to choose the amount of downforce required for the condition: 0 kg (0 lb), 56.7 kg (125 lb), 113.4 kg (250 lb), and 181.4 kg (400 lb).

Row Runoff diagnostic test

Row Runoff diagnostic test

The test functions from a mobile device

The test functions from a mobile device

Determine optimum settings without being in the cab

Determine optimum settings without being in the cab

The first day of planting season can be as productive as the last with mobile row-unit runoff. The mobile row-unit runoff activation on the planter main controller (PMC) allows operators to make adjustments to maximize row-unit performance from a mobile device at the rear of the planter for both preseason and in-season use - all enabled through the Equipment Mobile app.

Mobile row-unit runoff allows growers to perform test-stand functions from a mobile device connected to the planter.

The row runoff test provides complete diagnostic checks both preseason and in season. With the row-unit runoff test, the operator can make adjustments from the mobile device, including vacuum pressure, to determine the optimum meter and vacuum settings. This app functionality will help avoid making trips to the cab while validating meter performance.

During preseason planter inspections and set up, utilize the meter performance test to validate meter accuracy, similar to a test stand without leaving the farm. Test all systems on the planter, not just the meter, providing confidence that all planter systems are ready to plant. Reports are generated from the test providing information the operator can save and send for future reference.

Before heading to the field, the operator will benefit from knowing the best row-unit and vacuum settings for each variety selected to plant that spring.

Watch this video to see mobile row-unit runoff in action.

Mobile row-unit runoff will work with any model year 2015 or newer ExactEmerge™ or MaxEmerge™ 5e equipped planter. Mobile row-unit runoff can be added with attachment AA93169.

For model year 2018 and newer ExactEmerge planters, mobile row-unit runoff is included in base equipment. For model year 2020 and newer MaxEmerge 5e planters, mobile row-unit runoff is included in base equipment. For planters not equipped from the factory, mobile row-unit runoff can be added with attachment AA93169. A mobile row-unit runoff and Easy Fold package can be added with attachment AA97849 (only available with 1775NT and 1795 Planters with a 2-point hitch and model year 2019 and newer DB Planters with Gen 4 based frame folding).

NOTE: Mobile runoff utilizes the Equipment Mobile app available on select iPad® tablets, iPhone® smartphones, and Android™ devices.

Mobile row-unit runoff and Easy Fold aftermarket for field conversion kits

The below software bundles include the functionality explained above for machines not ordered with the feature from the factory. Compatible machines include all the necessary sensors and harnesses needed to make the feature function. The attachment part is software only. Follow the mobile runoff ordering and software push guide below for ordering and installation.

SeedStar™ 3 HP conversion to SeedStar 4HP

Mobile runoff ordering and software push guide

iPad and iPhone are trademarks of Apple Inc. Android is a trademark of Google LLC.

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

specs

| Number of rows | 12 |

| Row spacing | 76 cm 30 in. |

| Frame - Flexibility | Up and down: 21 degree (angle) |

| Row unit seed hoppers | Capacity 2.2 L 0.062 bu 58 L 1.65 bu 106 L 3.0 bu |

| Seed Meters | Base Vacuum Finger pickup Optional |

| Number of rows | 12 |

| Row spacing | 76 cm 30 in. |

| Flexibility | Up and down: 21 degree (angle) |

| Type | Wheel modules with hydraulic cylinders |

| Base | Implement tire: VF245/70R19.5 |

| Optional | Factory-installed Soucy tracks |

| Type | Standard: MaxEmerge™ 5 row units Optional: ExactEmerge™ row units MaxEmerge 5e row units |

| Opener | Tru-Vee double disk |

| Row unit seed hoppers | Capacity 2.2 L 0.062 bu 58 L 1.65 106 L 3.0 bu |

| Base | Vacuum |

| Finger pickup | Optional |

| Radial bean meter | Optional |

| Central Commodity System | Seed capacity 3524 L 100 bu |

| Base | Hydraulic variable rate drive |

| Type | Automatic alternating or independent control |

| Tank capacity | 1590 L 420 gal. |

| ExactRate Fluid Transfer System | Available |

| Transport width (with markers) | 3494 mm 137.56 in. |

| Transport length | 9197 mm 362 in. |

| Transport height | 3487 mm 137.3 in. |

| Field operation width | 9937 mm 391.2 in. |

| Field operation length | 6226 mm 245.1 in. |

| Recommended tractor horsepower | Minimum tractor size required: 90 kW 120 PTO hp Operating with extra planter attachments or when planting in soft seedbeds and rolling ground, more tractor power is required. |

| Recommended tractor hydraulics | Hydraulic oil required to operate machine: 5.7 L 1.5 gal. Hydraulic system working pressure: 20,684 kPa 206.84 bar (3000 psi) Hydraulic system burst pressure: 82,737 kPa 827.37 bar (12,000 psi) Tractor standby pressure: 15,514 kPa 155.14 bar (2250 psi) |

Similar Products

Prices and availability may vary by dealer. Taxes not included. Images for illustration purposes only. Financing subject to approved credit by John Deere Financial. Down payment may be required to receive financing. Restrictions may apply outside of Hutson’s area of responsibility. See dealer for details.