features

Our loader technology offerings are designed to enhance the material handling experience of your mid-model year 2022 and newer 6R 110 to 6R 250 Tractors when equipped with the electric joystick and mid-valves. Loader Technology includes the necessary harness, controller, sensors, and hardware to unlock four key features, making your material handling tasks easier and more efficient and taking advantage of the following.

- Dynamic Weighing System (DWS)

- Return to Position (RTP)

- Level to Horizon (LTH)

- Electronic self-leveling (ESL)

Loader Technology features when ordered.

Return to Position (RTP)

Return to Position (RTP) is a convenient feature enables the loader boom and bucket to automatically move to preset positions with ease. Operators can save specific boom upper height, lower height, and two different bucket angles for both settings A and B. To operate turn ON in RTP run page then simply engaging the joystick past a built-in detent, the loader dynamically responds to axis forward, back, left, or right, automatically returning the boom and bucket to the predetermined positions. Setting limits is easy from the RTP run page. To achieve this, set loader to the desired position then press the on-screen button. This function is particularly useful for repetitive tasks such as clearing a wagon, operating in a shed lower than max boom height, or setting a bucket angle for repeated dumping then returning bucket to zero. Additionally, re-zeroing implements is made easy with a dedicated zero button on the Return to Position (RTP) run page. Custom run pages can be created to incorporate RTP and DWS displays together to match your operating needs.

Mid-model year 2022 6R Tractor E-ICV joystick

Mid-model year 2022 6R Tractor E-ICV joystick

Dynamic Weighing System (DWS)

Dynamic Weighing System (DWS) feature offers real-time display of the current weight loaded on the loader attachment, such as a bucket, bale spear, or forks. This continuous weight monitoring eliminates the need for the tractor to stop for weighing, enabling the operator to accurately fill the bucket to the desired target weight without interrupting the workflow for a time-consuming weighing cycle. Furthermore, operators can easily record the weight with a simple push of the joystick button.

In addition, the DWS enables operators to create and save single material groups, such as bales, feed, or fertilizer, and even set up a material group comprising up to six different materials. The system displays and tracks the selected material group, providing a record of count, minimum, maximum, and average weights. Moreover, the weighing system can register multiple units. For instance, within a single material group, operators can count bales by 1, 2, or 3 during each loading cycle.

When operating the material group from the DWS run page, operators can simply select different stored material groups and record the weight as they load. As the weight is recorded, it counts down to zero, and a green checkmark appears next to the material to indicate completion, allowing the process to be repeated until all materials have been added. At any time while the material is being loaded, you can pause that material by selecting a different material then return to it at any time while using the material group. This is great for layering products into a feed wagon by not needing the mixer turned on and avoid over mixing.

A bar diagram and displayed values provide clear visual indicators of how much weight of the current component is still needed to reach its target weight.

The Dynamic Weighing System (DWS) is particularly valuable for use in windy feed yards. It enables operators to weigh lightweight commodities in the shed without the risk of blowing feed across the yard when delicately adjusting the load on the feed wagon to reach a target weight. This capability significantly enhances operational efficiency and helps maintain a clean feed yard environment, especially in challenging windy conditions.

Level to Horizon (LTH)

This feature ensures that the attachment is leveled parallel to the horizon, rather than maintaining the same angle as the tractor, as seen with conventional loader leveling systems. This means that when operating in hilly terrain, through waterways, or moving in and out of farm buildings, the pallet, fork, bucket, or other attachment actively adjusts the carrier to a horizontal position reducing the risk of spilling. If the operator prefers to maintain a different angle for specific tasks, they can easily disable this feature through the tractor display. It's important to note that Level to Horizon (LTH) is compatible with both self-leveling and non-self-leveling loaders. On display changes from LTH Level to Horizon to ESL Electronic self-leveling is effortless and is offered to best match your conditions.

Electronic self-leveling (ESL)

The Electronic self-leveling (ESL) feature ensures that the bucket positioning is maintained at any range of the boom. It can be conveniently activated or deactivated from the RTP run page, offering operators flexibility in controlling the leveling operation. Toggling between ESL and Level to Horizon (LTH) is as simple as selecting the desired leveling operation through the display. Furthermore, ESL is compatible with both self-leveling and non-self-leveling loaders, providing versatility and convenience for operators across different operating conditions and loader configurations. If you find yourself liking NSL loaders at times but require MSL during other loader operations, then maybe LTH or ESL could be right for you?

The loader technology offers several benefits that enhance efficiency and precision in material handling:

- Faster and easier loading of goods with the Return to Position (RTP) feature, eliminating the need for manual control of heights and angles to navigate around trailers and sheds.

- On-the-go weighing capability, saving time by eliminating the need to stop for weighing cycles and ensuring accurate loading without returning excessive feed to commodity location.

- Convenient loading from both sides of the feed wagon and rapid attainment of target weight in the bucket without interruptions waiting for weight.

- Precise dumping of weight into mixers, minimizing windblown commodity loss on the farm.

- Automatic bale counting with minimum, maximum, and average bale size, streamlining bale handling operations.

- Enhanced control and avoidance of spilling goods during transport with the Level to Horizon (LTH) feature, contributing to a cleaner and more organized material handling process.

Loader camera option when ordered with Loader Technology package (code 9662)

Tractor showing the loader camera image

Tractor showing the loader camera image

The loader camera offers visibility of the loader carrier and surroundings, providing a convenient view of the carrier's hooks for easy attachment connections. Additionally, when using pallet forks, the camera provides a clear view of the forks, facilitating effortless pallet handling. The video feed from the camera is displayed on the built-in display of the 6R Tractor.

The camera harness comes pre-installed inside the boom when Loader Technology has been optioned. The harness provided has an extended length of cable allowing for positioning the camera in a different location if desired, offering flexibility to accommodate specific operational preferences. Camera can be activated through a trigger such as forward direction or an SCV function.

Benefits

- Fast connection of attachments

- No damage to pallets and goods loaded on forks and spears

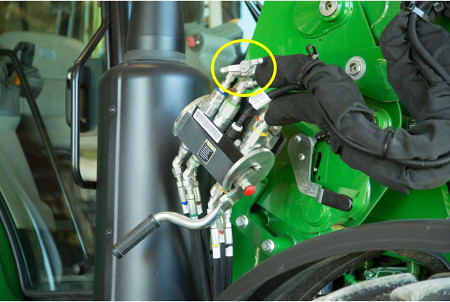

Single-point hydraulic connection on the 600R Loader

Single-point hydraulic connection on the 600R Loader

The R-Series Loaders feature a single-point hydraulic connection that saves the operator time when attaching or detaching the loader. This feature also incorporates the connection point for any electrical needs as well as the hydraulic lockout valve. With all hydraulic and electrical connections in one location, installation is quickly completed with the pull of a handle.

NOTE: Before disconnecting the hydraulic connection between the loader and the tractor, it is necessary to release the hydraulic pressure.

Single-point hydraulic connection (open)

Single-point hydraulic connection (open)

Single-point hydraulic connection (closed)

Single-point hydraulic connection (closed)

R-Series Loader attach and detach instruction video

600R Loader with concealed oil lines

600R Loader with concealed oil lines

The R-Series Loaders are designed to route the oil lines and hydraulic lines through the boom arm and the torque tube. This internal routing ensures better protection of the lines from external damage and improves the overall appearance of the loader.

600R Loader (side view)

600R Loader (side view)

600R Loader (angle view)

600R Loader (angle view)

New Mast Latch System for the 5R and 6R series loaders makes it easy to attach and detach the loader from the tractor. The system provides easy visual references from both the inside and outside of tractor cab. This feature provides a large pin that is inserted through the mast just above the latching mechanism, providing a quick visual reference from the operator station and during walk around inspections. This pin is attached to the loader with a cable with a convenient storage bracket when the loader is removed. When the loader is attached, the pin provides a sliding handle to assist with alignment and keeping the loader securely attached.

Mast Latch System pin installed in locked position

Mast Latch System pin installed in locked position

Mast Latch System pin in stored position

Mast Latch System pin in stored position

The inside of the loader mast has a new sticker that is easy to see from cab. This offers an indicator for when latched, to rest over the checkmark and provides a lock symbol just above the pin protrusion. The Mast Latch System is a pin and mechanical lever that allows operators to remove or attach the loader with one trip out of the cab.

Inside of mast shown from operator station

Inside of mast shown from operator station

https://johndeeredealers.hosted.panopto.com/Panopto/Pages/Sessions/List.aspx?folderID=cb4ec13e-373e-49ba-84e6-af970138c479

Hydraulic shut-off valve on R-Series Loader

Hydraulic shut-off valve on R-Series Loader

The R-Series Loaders come equipped with a hydraulic shut-off valve to improve serviceability. When conducting brief service to the loader, close the hydraulic shut-off valve to ensure the loader does not move while operating under the equipment. This feature promotes a safe way to conduct brief maintenance without having to use support stands or removing the loader completely.

600R Loader working with 6120M Tractor

600R Loader working with 6120M Tractor

The MSL R-Series Loaders utilize a false rod cylinder to improve bucket performance. This bucket cylinder is designed with a smaller displacement of oil required on the head end of the cylinder, which allows the cylinder to function more quickly, decreasing operation cycle time. With the false rod cylinder design, loader applications can work more quickly and efficiently.

False rod cylinders on 600R Loader

False rod cylinders on 600R Loader

specs

| Maximum lift height (A) | 4151 mm 163 in. |

| Lift capacity at full height | Measured at pivot (U) 2515 kg 5545 lb |

| Boom breakout force | Measured at pivot (Y) 2814 kgf 6204 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 4365 kgf 9623 lbf |

| Clearance at full height - bucket dumped (C) | 3141 mm 124 in. |

| Dump angle, degrees (E) | 59 degree (angle) |

| Rollback angle, degrees (G) | 52 degree (angle) |

| Model | 6110R/M, 6120R/M, 6130R/M |

| Front tire | 480/70R24 |

| Rear tire | 520/70R38 |

| Front axle configuration | MFWD w/ Limited Slip Differential |

| Wheelbase | 2580 mm 101 in. |

| Pump capacity | 114 L/min 30.1 gpm |

| Rated pressure | 200 bar 2900 psi |

| Base weight | 2072.3 kg |

| Leveling configuration | Non-Self Leveling (NSL) |

| Bucket used | Heavy-duty grapple 2450 mm Heavy-duty grapple 96 in. |

| Bucket weight | 375 kg 826 lb |

| Lift capacity at full height | Measured at pivot (U) 2515 kg 5545 lb Measured at 800 mm ahead of pivot (V) 1757 kg 3874 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 2654 kg 5851 lb Measured at 800 mm ahead of pivot (X) 2080 kg 4586 lb |

| Boom breakout force | Measured at pivot (Y) 2814 kgf 6204 lbf Measured at 800 mm ahead of pivot (Z) 2114 kgf 4661 lbf |

| Bucket rollback force capacity | At maximum height (VV) 2509 kgf 5531 lbf At 59-in. (1500-mm) lift height (XX) 4301 kgf 9482 lbf At ground-level line (ZZ) 4365 kgf 9623 lbf |

| Dimensions | Maximum lift height (A) 4151 mm 163 in. At full height - bucket level(B) 3911 mm 154 in. At full height - bucket dumped (C) 3141 mm 124 in. |

| Overall length (I+F), ft (m) | 5.4 m 17.6 ft |

| Digging depth (H) | 53 mm 2 in. |

| Reach | At maximum height (D) 993 mm 39 in. At ground level - bucket level (F) 2809 mm 111 in. |

| Bucket angle | Dump angle, degrees (E) 59 degree (angle) Rollback angle, degrees (G) 52 degree (angle) Dump angle, ground 144 degree (angle) |

| Cycle times | Loader raise, seconds 3.5 seconds Loader lower, seconds 2.63 seconds Bucket dump, seconds 2.65 seconds Bucket rollback, seconds 1.81 seconds |